Industrial Electrical Services by Light On Electrical: Sub Board Upgrade in Factories

05 September 2023

Elevate factory efficiency with sub board upgrades. Light On Electrical offers expert industrial electrical services. Power your production.

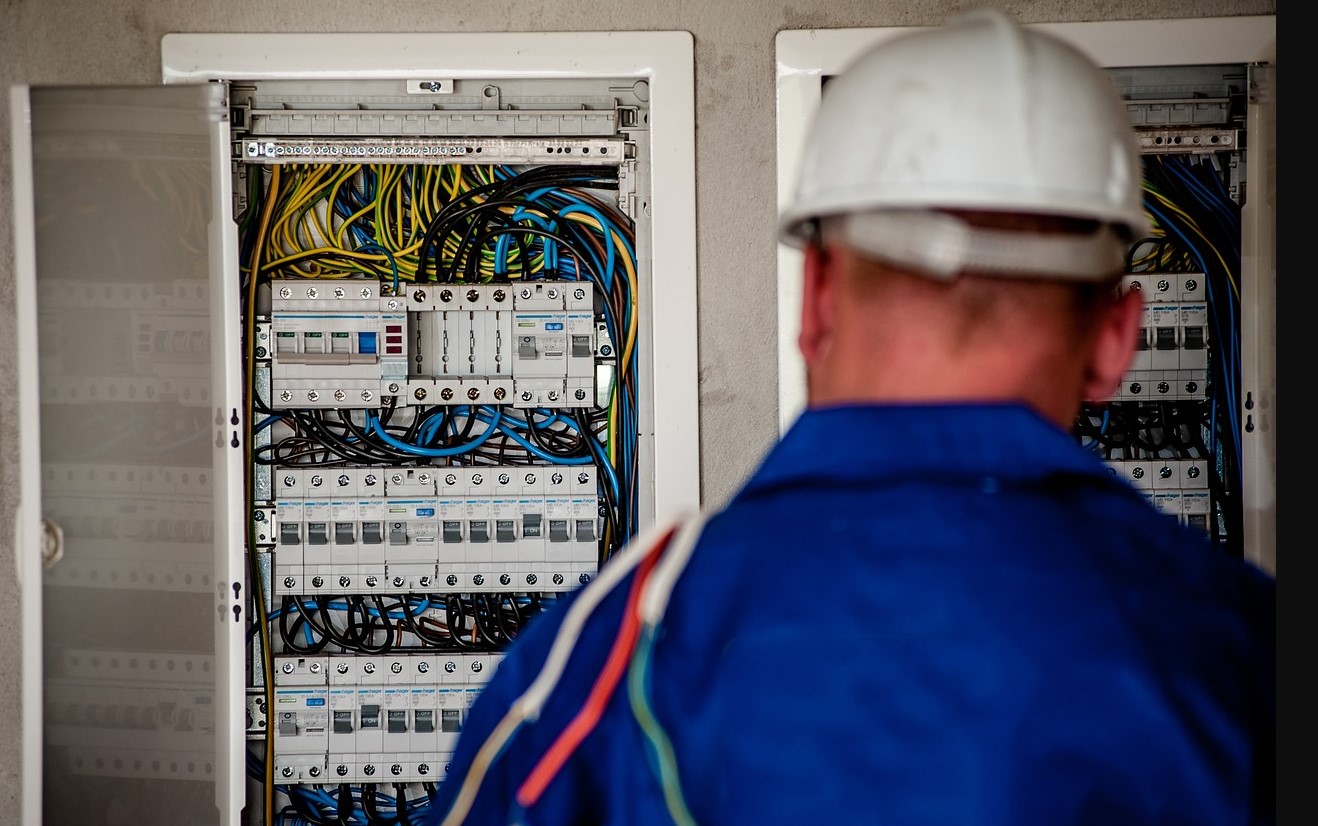

Most of the time, industrial buildings take advantage of the sub board or distribution board to effectively distribute electrical power to various circuits and equipment within their rooms and facilities. During its upgrade, the outdated or inadequate sub board is replaced with a new one to effectively accommodate higher electrical loads, incorporate advanced safety features, and meet the evolving needs of the electrical system.

One industrial building that can maximise a sub board upgrade is a factory. Factories rely on a wide variety of machines and tools. Without upgrading their existing sub boards, they may end up with issues that can affect their overall performance and safety.

Industrial Electrical Services and The Process of Sub Board Upgrade

Sub board upgrade involves multiple steps. These steps are as follows:

1. Assessment: An electrician evaluates the existing electrical system of a factory and determines the requirements for its sub board upgrade. This step involves assessing the electrical load, identifying safety deficiencies, and considering future expansion plans.

2. Design and Planning: Based on the assessment, a design plan is subsequently created by the electrician for the new sub board. The plan can be created and finalised by determining the size and capacity of the sub board, selecting appropriate circuit breakers and safety devices, and considering any specific requirements or regulations.

3. Installation: The installation process involves removing the old sub board and wiring, as well as installing the new sub board. The electrician is expected to connect the circuit breakers, ensure proper grounding, and integrate any additional safety or smart features.

4. Testing and Commissioning: Once the sub board installation is complete, thorough testing is conducted to ensure proper functions. Some activities involved in this step are checking for electrical continuity, verifying circuit connections, and conducting insulation resistance tests. The sub board is then commissioned and integrated into the overall electrical system.

All these steps are necessary to ensure proper sub board upgrade. This type of upgrade is often conducted in factories once they acquire new machines or equipment pieces. A sub board upgrade is also needed whenever factories expand or become outdated.

Sub Board Upgrade Major Benefits

If you are currently managing a factory, you must opt for a sub board upgrade whenever necessary to gain the following benefits.

• Improved Safety: Outdated sub boards often lack the necessary safety features, increasing the risk of electrical hazards like short circuits, electrical fires, or electrical shocks. Upgrading the sub board ensures compliance with the latest safety standards and codes, including proper grounding, surge protection, and circuit protection devices. It can also help cut the risk of electrical accidents and promote a safe working environment for employees.

• Enhanced Power Distribution: A sub board upgrade can also be done to reevaluate and optimise the power distribution within the factory. By strategically configuring circuits and ensuring proper circuit separation, the upgraded sub board can improve efficiency and minimise power loss. It also allows for more reliable and efficient power distribution to various equipment and machinery, reducing downtime and improving overall productivity.

• Integrated Smart Tech: Modern sub board upgrades often involve the integration of smart technologies like digital meters, energy monitoring systems, and remote monitoring capabilities. These advancements provide real-time data on energy consumption, power quality, and electrical performance, which allows factory managers to make informed decisions to optimise energy efficiency, reduce costs, and improve sustainability.

Sub board upgrades in factories are significant for efficient and safe operations. They not only improve the reliability and performance of the electrical system but also contribute to the overall productivity, safety, and sustainability of these places.

Optimized by NetwizardSEO.com.au